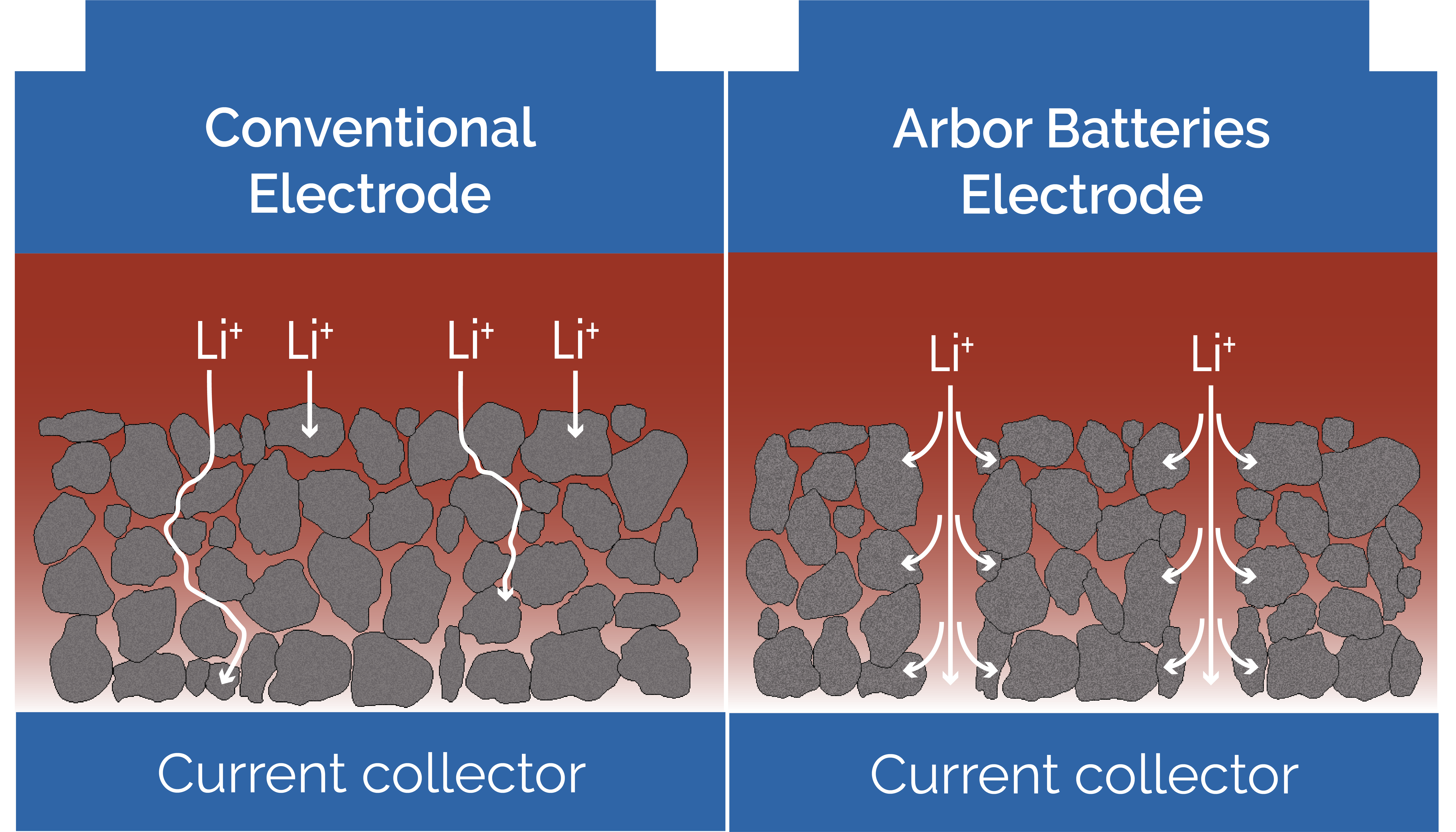

Electrode Architecture

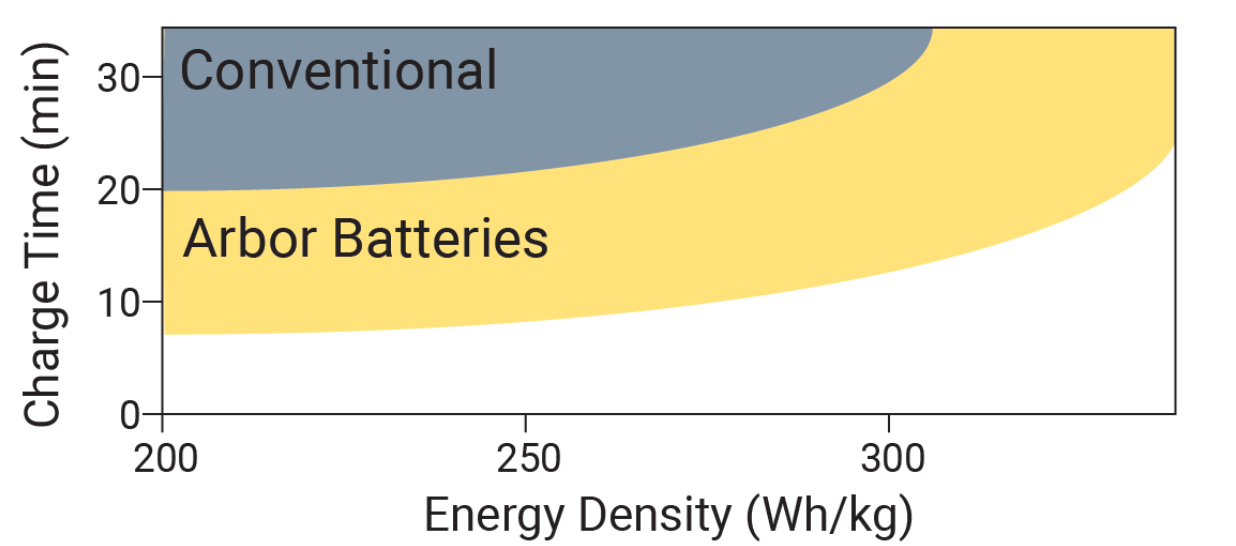

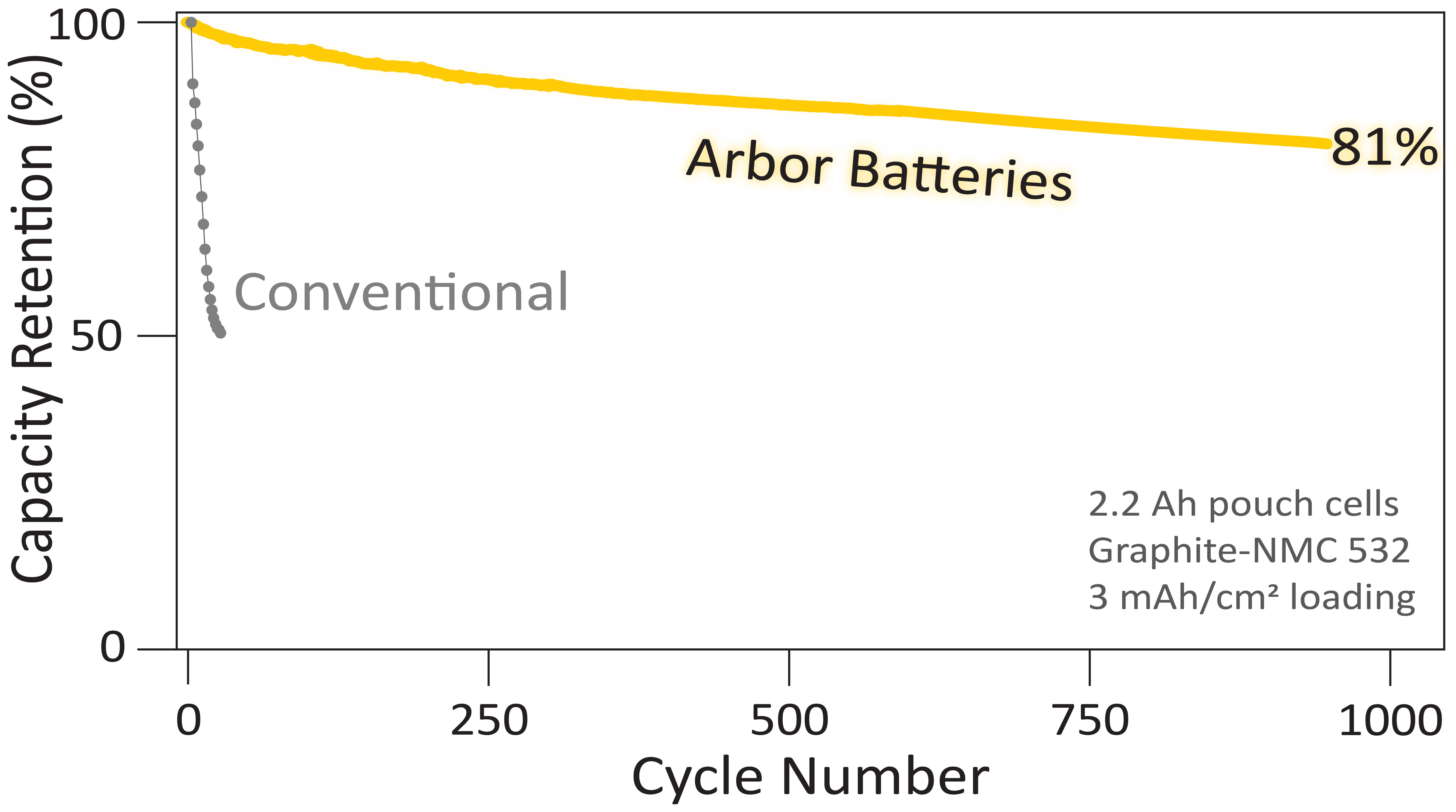

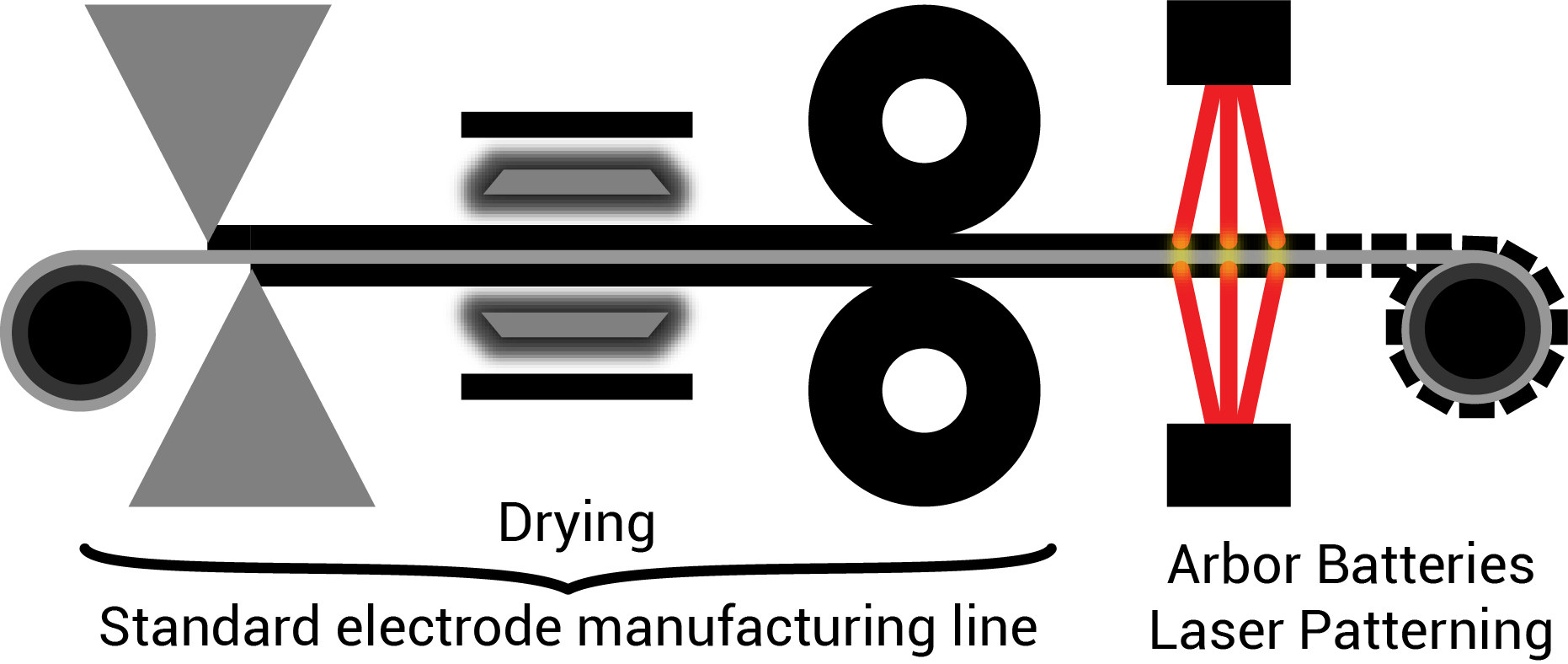

Arbor Batteries’ patented 3-D electrode architecture enables rapid transport of Li+ into the depth of even ultra-thick electrodes, promoting uniform intercalation. Uniform intercalation in the 3D electrode eliminates Li metal plating on the anode surface during fast charging.